How to Choose the Right Worm Gearbox for Your Industrial Application?

- Ankita Somani

- Jul 7, 2025

- 3 min read

Updated: Jul 14, 2025

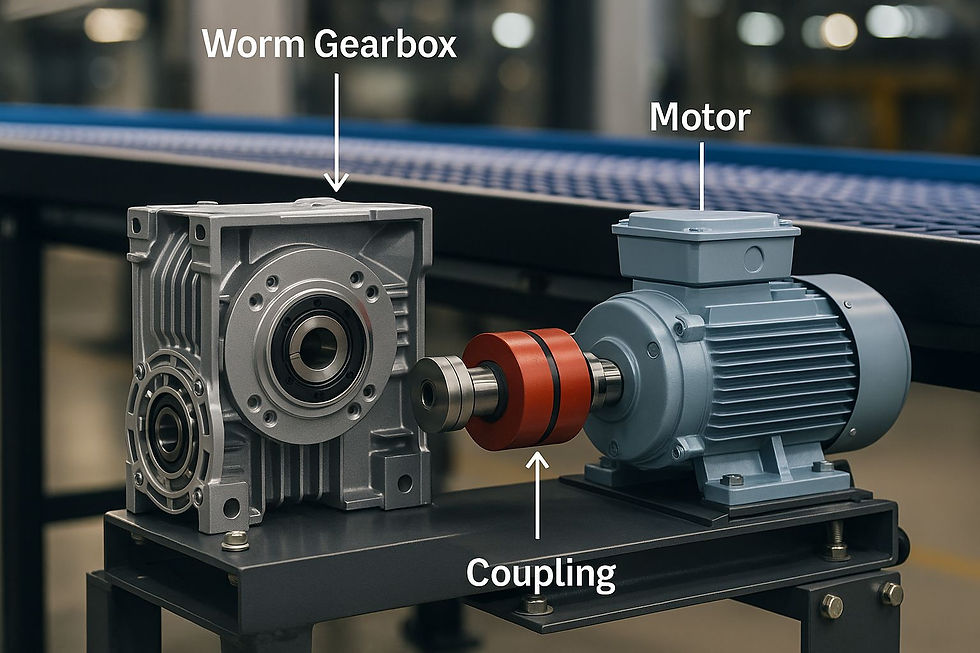

In the realm of heavy machinery and industrial equipment, selecting the appropriate gearbox is crucial for ensuring smooth and reliable operation while avoiding costly downtime. Worm gearboxes, such as the reputable IMPEL Worm Gearboxes distributed by Shree Krishna Sales, are among the most favored solutions for applications requiring precise speed reduction and high torque.

This guide will assist you in understanding the key considerations when selecting a worm gearbox to maintain efficient and safe production line operations.

The Importance of Selecting the Appropriate Worm Gearbox

A gearbox is more than just a component; it serves as the core of your machine’s power transmission system. Choosing an unsuitable gearbox can result in:

Inadequate torque or speed control

Excessive wear and mechanical failures

Elevated maintenance expenses

Inefficient energy consumption

Selecting the correct gearbox ensures:

Appropriate torque multiplication

Quiet and smooth operation

Extended equipment lifespan

Reduced maintenance and downtime

Key Factors to Consider When Selecting a Worm Gearbox

1. Load & Torque Requirements

Determine your machine's required output torque and power transmission needs. For instance, IMPEL worm gearboxes can accommodate output torque ranging from 100 to 4500 Nm, depending on the model.

Pro Tip: Opt for a gearbox with a torque rating slightly above your calculated requirements to ensure safety and longevity.

2. Gear Ratio & Speed Reduction

Worm gearboxes are renowned for their high reduction ratios. IMPEL EX Series models offer ratios from 7.5:1 up to 100:1, while cast iron units provide ratios from 10:1 to 60:1.

Consider the Following:

Do you require significant speed reduction?

Does your application necessitate precise speed control?

3. Mounting Options

Industrial setups vary, so your gearbox must be adaptable. IMPEL gearboxes feature universal mounting options (top, bottom, or side), facilitating integration into various machines such as:

Conveyors

Mixers

Lifts

Packaging lines

4. Body Material: Aluminum vs. Cast Iron

Aluminum Worm Gearboxes

Lightweight, compact design

Resistant to rust and corrosion

Ideal for food, packaging, and moderate load applications

Cast Iron Worm Gearboxes

Heavy-duty and durable

Handles high torque and harsh environments

Suitable for construction equipment, mining, and heavy machinery

5. Maintenance & Efficiency

Seek features such as:

High tensile strength worm wheels

Hardened and ground worm shafts

Double lip oil seals (to prevent leaks and dust ingress)

Pre-filled oil — ready for installation

These features ensure your gearbox remains efficient and low maintenance, reducing the likelihood of unexpected downtime.

Typical Uses for Worm Gearboxes

Key Areas of Excellence for Worm Gearboxes:

Manufacturing: Utilized in conveyors, rotary tables, and CNC machines

Construction: Employed in winches, hoists, and cement mixers

Agriculture: Applied in seeders, irrigation systems, and tillers

Food & Beverage: Used in mixers and filling lines

Automotive: Essential for assembly lines and lifts

Common Mistakes to Avoid in Gearbox Selection

Disregarding torque requirements

Selecting an incorrect gear ratio

Neglecting mounting and space limitations

Failing to consider corrosion and environmental factors

Why Buy from Shree Krishna Sales?

At Shree Krishna Sales, we’ve helped hundreds of industries find the perfect IMPEL worm gearbox for their specific needs. As an authorized dealer, we provide:

Genuine IMPEL gearboxes (EX Series and Cast Iron)

Custom solutions for unique applications

Expert guidance in sizing and selection

Fast delivery and local support across Pune and India.

Ready to Find the Right Worm Gearbox?

Whether you’re upgrading old equipment or designing a new system, Shree Krishna Sales is here to help.

Contact us today for expert advice and the best deals on IMPEL gearboxes.

Find us on Justdial

Or drop by our office in Pune

.png)

Comments